These sensors are very small and are designed for use in critical medical or biological applications, where the sensing instruments should provide a very low intrusion volume. Read More…

Honeywell offers a broad portfolio of pressure transducers for test and measurement in industrial, automotive/transportation, aerospace, and medical applications Honeywell’s pressure transducers are suited for both high and low temperatures. Products include strain gauge pressure transducers, differential pressure transducers, LVDTs and miniature pressure transducers. Customization is available ...

At Emerson Automation Solutions, we dedicate ourselves to advancing precision measurement and control technologies that empower industries to operate safely, efficiently, and sustainably. Our work in pressure transducers exemplifies this mission, as we engineer and manufacture high-performance sensors designed to provide accurate pressure readings under the most demanding industrial conditions.

We design and manufacture acceleration, pressure and weight sensing products. Setra makes fuel cell pressure transducers, industrial strain gauge pressure transducers, HVAC/R pressure transducers, ultra-high purity and vacuum pressure transducers plus other types. We've been in business since 1967.

Ashcroft® manufactures a full line of high-quality pressure transducers for reliable use in applications for high-volume OEM, general and heavy industrial and HVAC. Our line offers products with award-winning features. Our company realizes that as times change, so do the needs of industry. Products we manufacture have become the benchmark in our industry.

At Endress & Hauser, we take pride in being a global leader in process automation and instrumentation, dedicated to helping industries achieve precise measurement, control, and efficiency. Our expertise in pressure transducer technology allows us to deliver solutions that ensure reliable process monitoring and optimized system performance across a wide range of applications.

At ABB, we are driven by the pursuit of precision, innovation, and reliability in every solution we deliver. Our expertise spans across industrial automation, electrification, and advanced measurement technologies that empower industries to perform at their highest potential. As pioneers in process instrumentation, we design and manufacture high-performance pressure transducers that provide...

More Miniature Pressure Sensor Manufacturers

Miniature pressure sensors are composed of transducers, which are similar devices. Transducers convert one kind of energy into another kind; sensors, however, convert energy specifically to provide a readable measurement. Pressure sensors are classified according to the range of pressure they measure, the operating temperature range and the type of pressure they evaluate. There are five main categories of pressure sensors: absolute, differential, gauge, vacuum and sealed pressure sensors.

Practically any of these can be miniaturized. A typical pressure sensor is about a cubic inch in size, but miniature sensors can be a fraction of that size. They are usually comprised of at least two wires or probes attached to a round sensor. Usually ceramic, copper or metal components are used. Miniature pressure sensors are capable of accurately monitoring the pressure of fluid and can provide a cheaper alternative to flow sensors. They are used in weather instruments, aircraft and automobiles and can also monitor the engines in many different kinds of machinery.

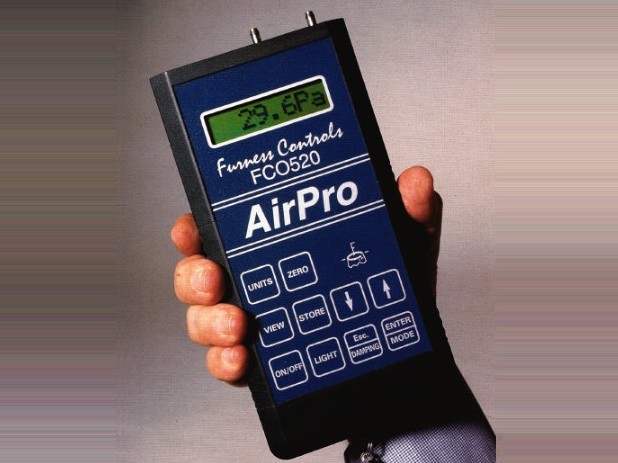

Pressure sensors use a variety of techniques to take measurements. In general, however, pressure sensors turn the physical force being exerted on them into a reading that can be represented by a gauge, dial or display. Air and atmospheric pressure sensors use a silicon diaphragm that bends depending on how much force is exerted on it. A charge running through it communicates to the sensor the corresponding pressure and the sensor displays it.

Advancements in technology and materials have enabled sensors to become smaller and more accurate. Integrated circuits in particular make miniature pressure sensors possible because they can be very small while still retaining all the necessary components. Pressure sensors can benefit from the use of calibrators and regulators. Pressure calibrators are devices that measure the pressure and then compare that to what the pressure sensor reads.

They help maintain accuracy, which is important for many pressure systems. Sensors are able to detect and report pressures with a margin of error less than one percent. Pressure regulators monitor and control the actual flow of pressure and are often found directly on a nozzle or valve. As a safety and loss management precaution, regulators and sensors can be programmed to alert operators if the system's pressure is too high or too low.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services