More Pressure Transducer Manufacturers

Pressure transducers are essential components in both industrial and commercial environments, where accurate pressure monitoring and control are crucial for the reliability and safety of all fluid power systems, including hydraulic and pneumatic applications. The ability to precisely measure and convert pressure data into usable signals underpins processes across industries such as manufacturing, automotive, oil and gas, HVAC, medical devices, semiconductor fabrication, and environmental monitoring.

Establishing Definitions of Pressure Transducers

Pressure transducers, sometimes referred to as pressure transmitters or pressure sensors, are often not as clearly defined as other industrial measurement devices. To clarify their functionality and aid in product selection, it is helpful to contrast them with similar but distinct technologies.

The terms “pressure sensor” and “pressure transducer” are frequently used interchangeably. However, understanding their subtle differences is important for engineers, maintenance professionals, and procurement specialists:

- A pressure sensor detects and responds to physical pressure changes. It may or may not convert this information into another format.

- A pressure transducer not only senses pressure but also converts it into an electrical (or sometimes optical) output, making the information easier to interpret, record, transmit, or control.

Although most modern pressure sensors are also transducers, recognizing this technical distinction is useful when specifying components for critical systems or when adhering to industry standards.

It is also valuable to differentiate pressure transducers from load cells. While load cells are a type of transducer designed to convert mechanical force into an electrical signal (commonly used for weighing), not all pressure transducers are load cells. Pressure transducers specifically measure pressure (force per unit area, in units such as Pascals, bars, or psi), whereas load cells directly measure force (in Newtons or pounds-force). Some pressure transducers use different output formats, including optical or frequency-based signals, broadening their scope of application.

Pressure Transducer Production

Contemporary high-accuracy pressure transducers are constructed from a variety of robust and corrosion-resistant materials to ensure longevity and reliability in demanding environments. The primary structural elements are typically made from stainless steel, titanium, ceramic, copper, or carbon composites. The wetted materials—components that come into direct contact with process fluids—may also include bronze, plastics (such as PTFE for chemical compatibility), glass, and silicon.

Sizing is highly application-dependent. A standard industrial pressure sensor may measure about one cubic inch, but miniature pressure transducers can be as compact as 1/100th of a cubic inch, essential for medical devices, aerospace, and micro-electromechanical systems (MEMS).

How Pressure Transducers Work

Regardless of the specific type, all pressure transducers operate on the basic principle of converting mechanical pressure into an electrical signal. This process typically involves a sensing element—such as a Bourdon tube, bellows, or diaphragm—that deflects under pressure. The movement or strain of this element alters an electrical characteristic (such as resistance, capacitance, or frequency), which is then measured and translated into a pressure reading.

- Strain Gauge Pressure Transducers: These are the most widely used type in industrial automation, process control, and fluid power systems. They use a strain gauge—a thin, conductive foil or semiconductor—that changes resistance when stretched or compressed by pressure-induced deformation of a diaphragm. Wired in a Wheatstone bridge circuit, these transducers provide accurate, stable, and repeatable output, making them ideal for high-pressure and dynamic measurement scenarios.

- Piezoelectric Pressure Transducers: These transducers utilize the piezoelectric effect, generating an electrical charge in response to applied pressure. Their fast response time makes them ideal for dynamic pressure measurement applications, such as engine monitoring, explosion testing, or vibration analysis.

- Capacitive Pressure Transducers: By measuring changes in capacitance caused by diaphragm deflection, these transducers are highly sensitive and well-suited for low-pressure or vacuum applications. Common uses include HVAC systems, cleanroom monitoring, and medical breathing apparatus.

- Resonant Pressure Transducers: These devices measure pressure by detecting shifts in the natural frequency of a vibrating element. They are valued for exceptional long-term stability and are used where drift-free measurements are critical, such as in calibration labs and reference instrumentation.

- Thermal Pressure Transducers: Devices like Pirani gauges utilize changes in a gas’s thermal conductivity to infer pressure, making them indispensable in vacuum technology and semiconductor manufacturing.

Types of Pressure Transducers

Pressure transducers can be classified in several ways to help engineers and buyers select the right device for their application. Understanding these categorizations is crucial for optimizing system performance, reducing downtime, and ensuring regulatory compliance.

Categorizing by Types of Output

Most pressure transducers require an external excitation voltage or current to operate. Their output signal—the converted representation of the measured pressure—can take several forms:

- Millivolt Output Transducers: Provide low-level analog signals (typically ≤ 30 mV). They are highly sensitive but susceptible to electrical noise, best used in short-distance or shielded environments.

- Voltage Output Transducers: Deliver amplified analog signals (e.g., 0-5V, 0-10V), less sensitive to interference and suitable for moderate distances.

- Current Output Transducers (Pressure Transmitters): Often called 4-20 mA pressure transmitters, these devices are preferred for long cable runs and noisy industrial settings due to their resistance to signal degradation.

- Frequency Output Transducers: Output frequency-modulated signals proportional to pressure, used in specialized process control systems.

- Optical Output Transducers: Use changes in light transmission or wavelength in fiber optics to detect pressure, ideal for explosive atmospheres or high-voltage areas.

Categorizing by Measuring Standards

Pressure transducers are also grouped by the reference standard against which they measure pressure:

- Gauge Pressure Sensors: Measure pressure relative to ambient atmospheric pressure; ideal for tire pressure monitoring, process tanks, and industrial machinery.

- Sealed Pressure Sensors: Reference a fixed pressure (often atmospheric at sea level), used in hydraulic systems or subsea applications where venting to the atmosphere is impractical.

- Vacuum Pressure Sensors: Detect pressures below atmospheric, essential for vacuum pumps, laboratories, or semiconductor fabrication.

- Absolute Pressure Sensors: Measure pressure relative to a perfect vacuum, vital for barometric measurement, altitude determination, and scientific research.

- Differential Pressure Sensors: Measure the difference between two points, commonly used for filter monitoring, flow measurement, and HVAC duct balancing.

Categorizing by Measured Phenomena

Some pressure transducers are designed for specific phenomena or media:

- Blood Pressure Transducers: Used in medical equipment for patient monitoring and diagnostics.

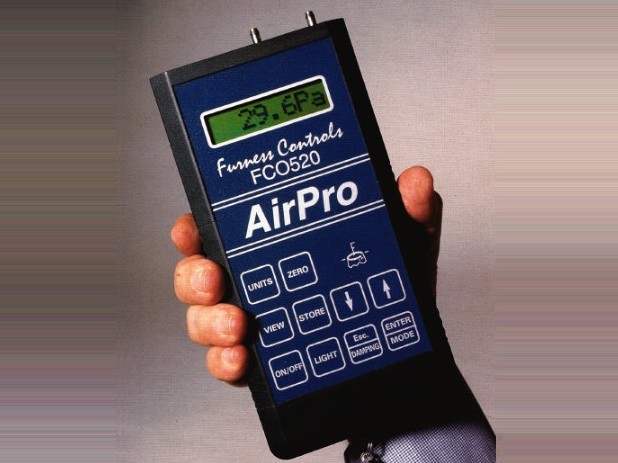

- Air Pressure Sensors: Employed in pneumatic tools, compressors, weather stations, and barometric applications.

- Liquid Pressure Sensors: Integral to hydraulic systems, fluid dispensing, and process control in chemical plants.

- High-Temperature Pressure Transducers: Built to withstand harsh thermal environments, such as combustion chambers or industrial furnaces.

Application-Specific Categorization

Pressure transducers are also categorized by the applications they serve. Common examples include:

- PC Board Mountable Transducers: For integration into electronics, instrumentation, and IoT devices.

- Heavy-Duty/Industrial Pressure Transducers: Designed for durability in process plants, oil and gas fields, and construction machinery.

- Miniature Pressure Transducers: Essential for minimally invasive medical devices, aerospace navigation, or robotics.

- High-Accuracy Laboratory Transducers: Used in calibration services and reference standards.

Categorizing by Size

Miniature transducers, some less than 1 mm3, enable biomedical procedures, catheter-based pressure monitoring, and integration into compact or portable equipment. Their low error margins and high reliability are maintained through precise calibration and redundancy.

Pressure Transducer Accessories

To optimize performance, reliability, and integration of pressure transducers within larger systems, a variety of accessory devices are frequently used. These include:

- Pressure regulators

- Pressure calibrators

- Level transmitters

- Torque transducers

- Temperature transducers

- Integrated circuits (ICs)

Pressure Regulators: These devices maintain a desired pressure level within a system and often feature programmable alarms to notify operators if the pressure exceeds safe operating thresholds. Pressure regulators come in various forms, such as back pressure regulators (BPR), vacuum regulators, differential pressure regulators, and pressure reducers, each tailored to specific fluid types (air, oil, fuel, steam, etc.) and applications.

Back Pressure Regulators:

- Maintain set pressure upstream, releasing excess when input exceeds the setpoint.

- Apply to upstream pressure management in process systems, prevention of overpressure damage, vent and flare line regulation, and safety in hyperbaric and diving environments.

Pressure Reducers:

- Reduce high supply pressure to a controlled lower output, as required in aerospace, industrial gas, cooking, and medical gas delivery.

- Support safe operation of gas-powered equipment and ensure regulatory compliance in mining and chemical industries.

Pressure Calibrators: Used to verify, adjust, and document the accuracy of pressure measurement devices. They are crucial for preventive maintenance, regulatory audits, and ensuring traceability in pharmaceutical, food processing, and energy production.

Level Transmitters: Measure the level of solids, liquids, or slurries in containments, providing critical data for tank monitoring, inventory control, and spill prevention.

Torque and Temperature Transducers: Expand the range of process monitoring by measuring rotational force (torque) and temperature, often in tandem with pressure sensors in motors, turbines, and combustion engines.

Integrated Circuits (ICs): Increasingly, pressure transducers are equipped with silicon chips and microprocessors for digital signal processing, enabling features such as remote monitoring, self-diagnostics, and network connectivity for Industrial IoT (IIoT) applications.

Considerations for Pressure Transducers

Selecting the right pressure transducer is vital for optimal system performance, safety, and regulatory compliance. Here are key factors to evaluate:

- Application Requirements: Define the process media, expected pressure range, accuracy needs, and environmental conditions. For example, millivolt output transducers are economical but sensitive to electrical interference, while current transmitters (4-20 mA) excel in industrial and long-distance wiring scenarios.

- Physical Environment: Consider threats such as over-pressurization, temperature extremes, vibration, corrosion, and EMI/RFI interference. Protective housings and careful installation can enhance device lifespan.

- Safety Margins: Choose a pressure transducer with a maximum rated pressure well above expected operating conditions. Maintain a safety margin (typically operating at 50-60% of the device’s maximum range) to absorb pressure spikes and avoid sensor fatigue.

- Protective Measures: Incorporate snubbers or pressure dampeners to shield transducers from sudden pressure surges.

- Temperature Compensation: For environments with temperature fluctuations, select high-temperature or temperature-compensated pressure transducers to ensure consistent accuracy.

- Output Signal Compatibility: Match transducer output to your control system (PLC, SCADA, DCS, or data logger) to ensure seamless integration and avoid conversion errors.

- Calibration and Maintenance: Regular calibration is essential for ongoing accuracy, especially in regulated industries.

- Certification and Standards Compliance: Ensure the device meets relevant standards (CE, RoHS, ATEX, ISO 9001) for your industry and jurisdiction.

Frequently Asked Questions About Pressure Transducers

- How do I select the right pressure transducer for my application?

- Consider process media, pressure range, accuracy, output type, environmental conditions, and industry certifications.

- For hazardous locations, choose explosion-proof or intrinsically safe models.

- Consult with manufacturers to match transducer specifications to your process requirements.

- What are the most common failure modes for pressure transducers?

- Over-pressurization, exposure to incompatible media, electrical surges, temperature extremes, and physical shock.

- Implementing proper installation and periodic maintenance can significantly reduce failure risk.

- When should I recalibrate my pressure transducer?

- Follow manufacturer guidelines, but recalibrate at least annually or after exposure to significant process events (e.g., overpressure incidents).

- Industries with stringent quality standards (pharmaceutical, aerospace, food and beverage) may require more frequent calibration.

- Can pressure transducers be used for both gases and liquids?

- Yes. Ensure wetted materials are compatible with the measured media to avoid corrosion or contamination.

- How does temperature affect pressure transducer performance?

- Temperature swings can cause drift, offset errors, or material fatigue. Use temperature-compensated or high-temperature-rated transducers as needed.

Considerations for Pressure Transducer Supplier Selection

Choosing the right pressure transducer supplier is critical to achieving reliable operation, minimizing downtime, and ensuring regulatory compliance. Key factors in supplier evaluation include:

- Product Breadth and Depth: Look for suppliers offering a comprehensive range of pressure transducers and related instrumentation, including customized solutions for unique environments.

- Industry Experience: A supplier with extensive experience in your industry (e.g., oil and gas, chemical processing, medical devices, HVAC) can provide valuable guidance and reduce the need for extensive in-house testing.

- Technical Support and Training: Seek partners that offer in-depth technical resources, application engineering support, and training to ensure correct selection, installation, and maintenance.

- Certifications and Quality Assurance: Prioritize suppliers with robust quality management systems and compliance with industry standards (ISO, ATEX, CE).

- Terminology Clarity: Pressure transducer specifications can vary among manufacturers, especially regarding resolution, accuracy, and response time. Ask detailed questions about these parameters to ensure you are comparing like-for-like.

- Lead Times and After-Sales Support: Assess supplier responsiveness, delivery schedules, and their ability to provide ongoing support, calibration, and repair services.

Optimize Your Pressure Measurement Systems

Pressure transducers are a cornerstone of modern industry, enabling safe, efficient, and automated operation across a vast range of processes. Whether you are upgrading an existing system, specifying components for a new build, or troubleshooting process issues, choosing the right pressure measurement solution is key.

- Need help selecting the ideal pressure transducer for your application? Browse our directory of leading pressure transducer manufacturers and compare specifications, certifications, and application expertise.

- Curious about integrating pressure measurement with digital control systems? Explore our resources on pressure transmitters, regulators, and IIoT-enabled devices.

- Wondering how pressure transducers fit into your industry’s best practices? Contact us for application-specific advice or request a quote from our network of trusted suppliers.

By understanding the various technologies, output formats, application requirements, and supplier considerations, you can make informed decisions that support operational excellence, regulatory compliance, and long-term process reliability.

What is the difference between a pressure sensor and a pressure transducer?

A pressure sensor detects and responds to physical pressure changes but may not convert this information into another format. A pressure transducer, on the other hand, senses pressure and converts it into an electrical or optical output, making it easier to interpret, record, or control within a system.

How do pressure transducers work?

Pressure transducers convert mechanical pressure into an electrical signal. This is usually achieved by a sensing element such as a Bourdon tube, bellows, or diaphragm that deflects under pressure. The deflection alters an electrical property—like resistance, capacitance, or frequency—which is then measured and translated into a pressure reading.

What are the main types of pressure transducers?

The main types include strain gauge, piezoelectric, capacitive, resonant, and thermal pressure transducers. Each type uses a different method—like electrical resistance change, piezoelectric charge, capacitance shift, frequency shift, or thermal conductivity—to measure and convert pressure into a readable signal.

How are pressure transducers categorized by output signal?

Pressure transducers are categorized by output signals as millivolt output, voltage output, current output (such as 4-20 mA), frequency output, and optical output. These different formats suit various environments, distances, and system compatibility needs.

What materials are used to construct pressure transducers?

High-accuracy pressure transducers are constructed from robust and corrosion-resistant materials such as stainless steel, titanium, ceramic, copper, carbon composites, and sometimes bronze, plastics (like PTFE), glass, or silicon for wetted parts that contact process fluids directly.

What should I consider when selecting a pressure transducer?

Consider your application requirements, including process media, pressure range, required accuracy, output signal type, environmental factors (such as temperature and vibration), required certifications, and compatibility with your control system. It is also important to ensure proper calibration and account for safety margins.

What accessory devices can be used with pressure transducers?

Common accessories include pressure regulators, pressure calibrators, level transmitters, torque and temperature transducers, and integrated circuits (ICs). These devices can help ensure optimal performance, extend sensor lifespan, and facilitate integration with larger process control systems.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services